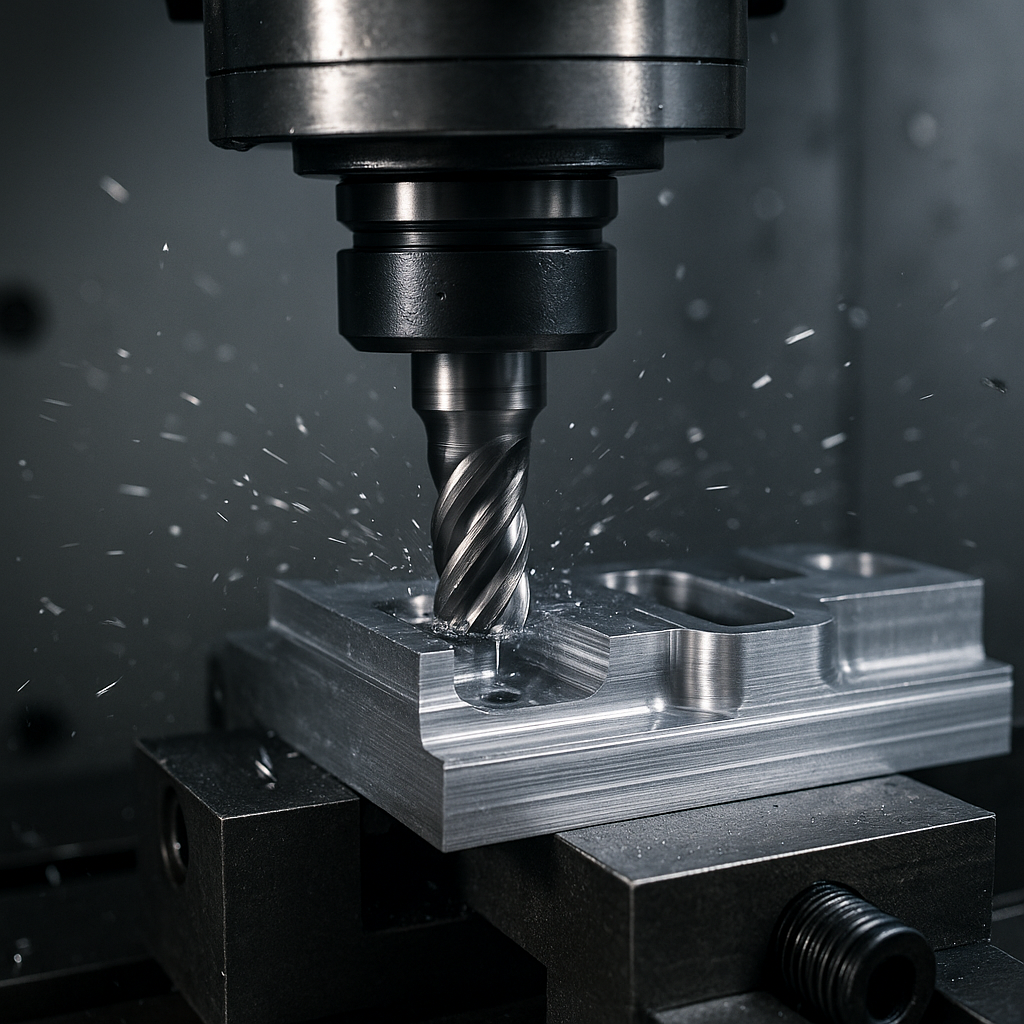

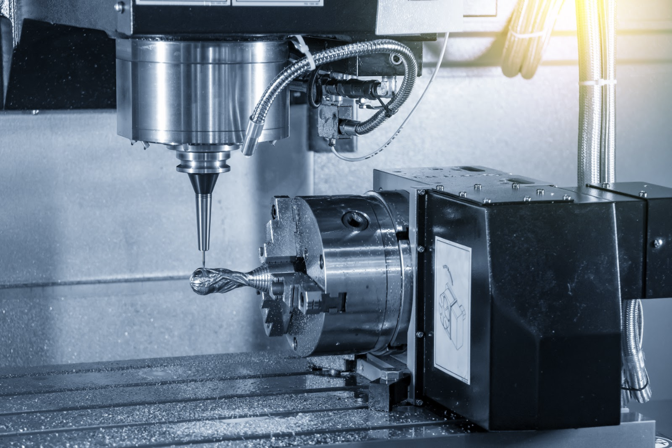

We specialize in high-precision CNC machining for metal components, delivering tight tolerances and exceptional surface finishes. Whether you need complex prototypes or high-volume production, our advanced equipment and attention to detail ensure consistent accuracy and quality. From small parts to intricate assemblies, we’re committed to meeting your exact specifications—on time and to the highest standards.

Our Capabilities

Our shop is equipped with advanced 3- and 4-axis CNC machines, allowing us to produce complex, high-precision parts with increased efficiency and flexibility. With 3-axis capabilities, we handle a wide range of milling tasks with tight tolerances, while our 4-axis machines enable enhanced contouring and multi-face machining in a single setup—reducing lead times and improving accuracy. This combination lets us tackle intricate geometries and deliver consistent, high-quality results for both prototypes and production runs.

Material Selection

Aluminium

- 6061

- 7075

- 2024

- 5052

- Additional Upon Request -

Stainless Steels

- 303

- 304

- 316 / 316L

- 410

- 420

- Additional Upon Request -

Steels

- 1018

- 1045

- 1215

- 4130 / 4140 Chromoly

- A36 Mild

- 8620

- Additional Upon Request -

Copper

- C101 / C110 (Oxygen-Free Copper)

- C145 (Tellurium Copper)

- Additional Upon Request -

Brass / Bronze

- C360 (Free-Machining Brass

- C932 (Bearing Bronze

- C954 (Aluminum Bronze)

- Additional Upon Request -

Tool Steel

- A2

- D2

- O1

- S7

- H13

- Additional Upon Request -